SINTEF

SINTEF Battery Lab: Enabling the Future of Battery Innovation

At the SINTEF Battery Lab, we provide a cutting edge, collaborative space for battery research, prototyping, and small-scale production. Our facilities bring together experimental and modelling teams to support the entire battery value chain, from materials validation to cell assembly and testing.

Visiting Address: SINTEF, Bratsbergvegen 5, 7031 Trondheim

Dry room – Controlled environment for Advanced Battery Research

Our advanced dry room spans 150 m², consistently maintaining an ultra-low dew point of -60 °C, and comfortably accommodates up to six operators at once and includes:

- Dedicated mixing area with a fume hood for the safe handling of nanoscale materials.

- Pilot Coating line for precision electrode coating.

- Pilot Pouch Cell Assembly line for prototyping and small-batch cell production up to TRL 6.

Mixing Unit – Scalable Precise Slurry Preparation

The slurry is initially prepared in the mixing room using an EIRICH EL5 ProfiPlus Intensive Mixer with a 5 L capacity, utilizing either water or an organic solvent, depending on the specific electrode chemistry. The system is water-cooled to maintain a low temperature during mixing. Once the slurry is prepared, it is subjected to vacuum degassing using an integrated degasser unit to remove entrapped air. The slurry rheology can then be characterised by an ANTON PAAR MCR 302e Rheometer and its resistivity tested by a BSR2300 analyser.

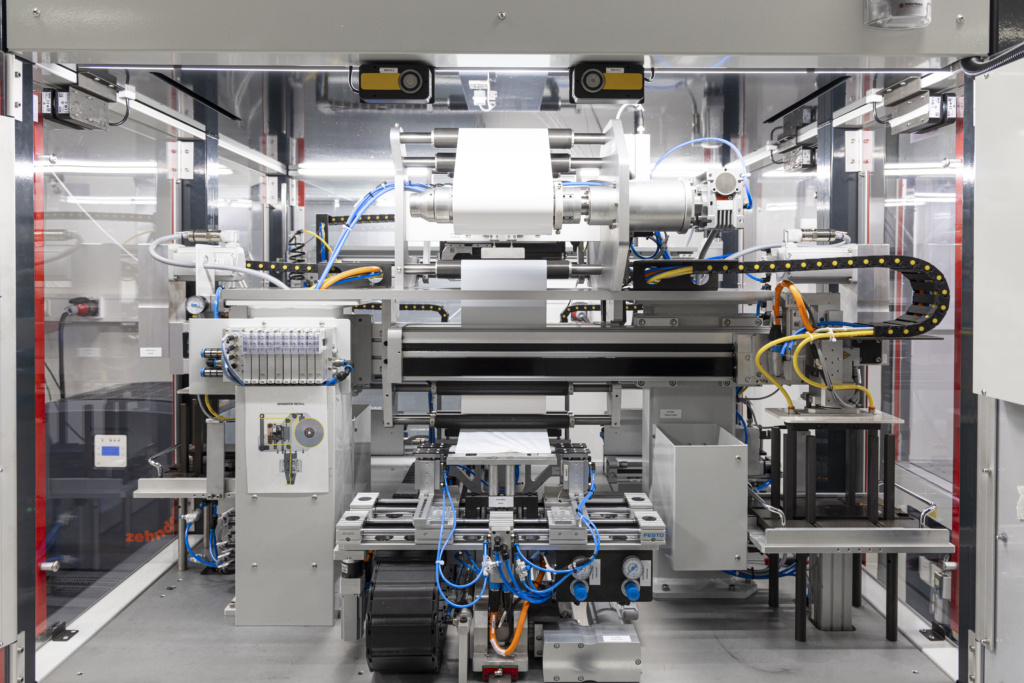

Pilot Coating Line – Roll to Roll Precision Coating and Calendaring

Consisting of a roll-to-roll coater and a heated calendaring machine that are supplied by Werner Mathis AG equipped with mass loading and edge sensors with precision alignment and gap control.

- Coating types: Doctor blade or slot-die coating for both single- and double-sided applications

- Coating width: 150 mm and 200 mm

- Coating speed: Variable, starting from 0.1 m/min

- Drying system: Combination of infrared heating and two 1-meter hot air ovens, with adjustable temperature and airflow; integrated exhaust channel for efficient solvent vapor removal

- In-line quality control: Real-time coating uniformity monitoring (Mesys)

- Calendar: Heated rollers that can apply up to 45 tons of line pressure.

- Electrode Resistivity: Tested with a BER2500 analyser together with thickness and compaction density

Pilot Pouch Cell Assembly Line – Seamless Electrode to cell prototyping

The line is supplied by Digatron of 6 stations with operators transferring inputs and outputs between stations. Electrodes are first punched then Z-stacked before having the tabs welded and the cell stack layered into the cell housing. Thereafter the cell stack is dried under vacuum and then the electrolyte injected to have a cell ready for formation. The line can produce up to 20Ah multilayer pouch cells.

Cell formation and Testing Facilities

We offer comprehensive cell testing and formation protocol prototyping capabilities. A variety of testers of different current capability exist.

- Novonix Ultra High Precision Testers: Measures Coulombic Efficiency, up to five significant figures, to enable reliable comparisons of cells in a fraction of the time that it would take on other cyclers. 20A, precision 2nA, 16 Channels

- High current 60A Testers 64 Channels

- Small current testers 20mA-6A >400 Channels

- Biologic potentiostats + 3-Electrode PAT cells

- Formation system, 64 Channels: Formation under applied and controlled pressure and temperature

- Explosion proof test chambers: Temperature controlled between -40°C to 150°C with fire suppression

- Cell expansion Tester: Tests cell expansion as a function of cycling, electrolyte/anode formulation.

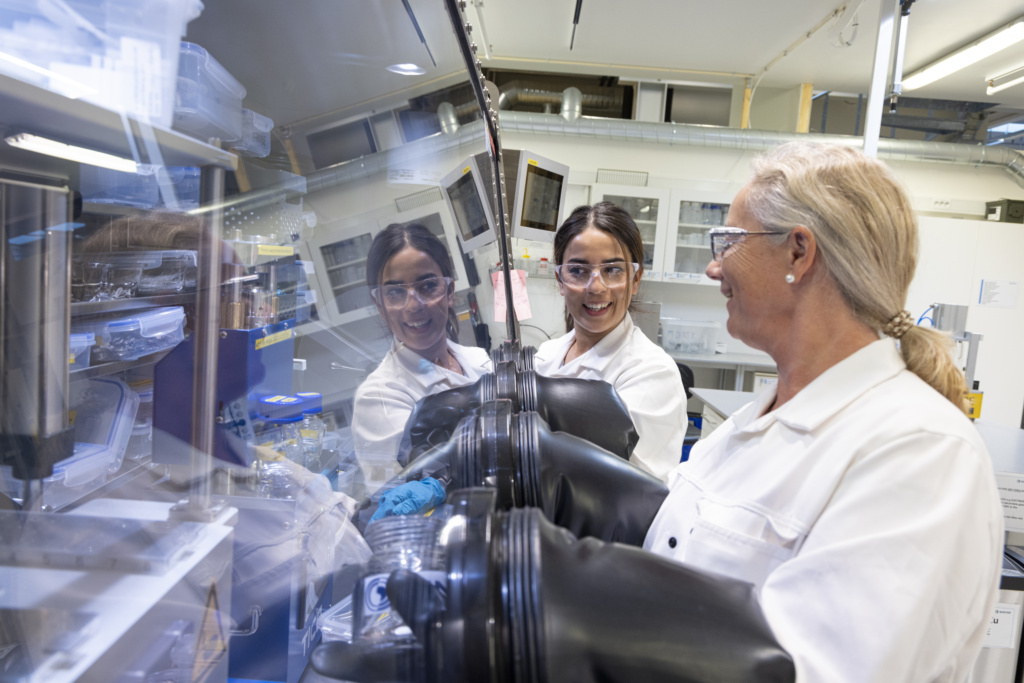

General lab

The space hosts the small-scale battery technology development facilities and includes gloveboxes, drying/vacuum ovens, benchtop sheet and drum coaters, rheometer and fume hoods among other equipment and facilities.

Partner with the SINTEF Battery Lab

Whether you’re a startup, materials innovator, or battery manufacturer, SINTEF Battery Lab offers the facilities and expertise to support your next-generation battery development and scale up ambitions:

Contact us today to explore collaboration opportunities.

Paul Inge Dahl +4798243955 paulinge.dahl@sintef.no