IFE

IFE is the coordinator of NABLA and hosts a prototype pouch cell line for making, testing, validating and prototyping of battery materials and components. The laboratory was established in 2023 and has an area of 500 m2, providing unique infrastructures for validation of battery materials in Norway.

Mixing and coating

Active components of a battery electrode are first mixed together with a binder and a conductive agent. At IFE there are several mixers of different sizes and attributes to choose from, providing flexibility in needed material amounts. All slurries are water-based and the properties of the slurries are coupled with rheology measurements.

- Slurry mixing: Eirich EL1, Eirich CleanLine C5 with degassing and EX approval.

- Processing volume: 300 mL – 5 L

- Solvent type: water-based

- Pump transfer to coater

- Rheology: Anton Paar MCR 302e

When the slurry is ready, the electrode is ready to be cast. In a clean room, IFE has set up a 9-m long roll-to-roll slot die coater from FOM Technologies.

- Type: Single- and double-sided coating

- Room: Clean room (ISO8)

- Coating width: 140 mm, 300 mm

- Coating thickness: tens to hundreds of microns

- Coating speed: 0.1-15 m/min

- Drying method: IR, air circulation in 3 individually operated ovens which can heat up to over 200 °C each

- Calendaring: Stainless steel calendaring unit

- Optional processing: lamination, electrode slitting to custom width

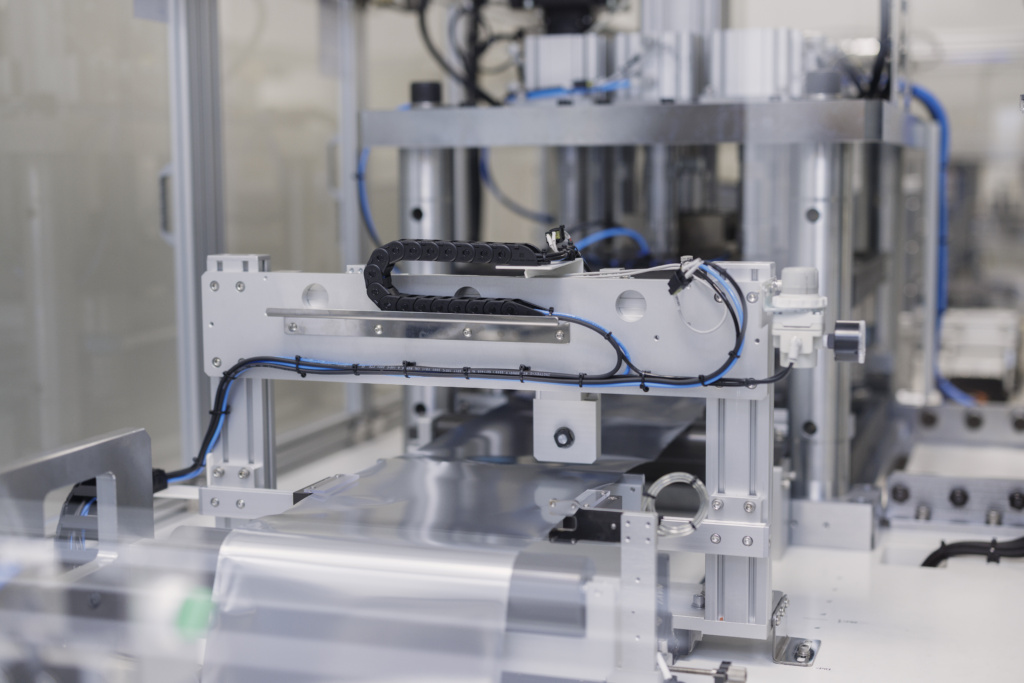

Cell assembly

Our own produced electrodes, or commercially electrodes can be assembled into pouch cells at IFE. We have a semi-automatic pouch cell line which provides flexibility in cell size and cell capacity, to ensure relevance in a wide range of projects.

- Type: Multi-layer pouch cells, single-layer pouch cells

- Room: Clean and dry room (ISO8, -40 °C dew point), Capacity: 4 people

- Automated steps: Notching, Stacking, Tab welding, Pouch forming, Side sealing, Electrolyte filling, Rolling & degassing.

- Pouch cell sizes: P01 – 155 x 81.6 mm (anode: 117×60 mm, cathode; 115×58 mm width) . P02 – 233 x 142 mm (anode: 195×118 mm, cathode: 197×120 mm). Stacking amount and thickness is customizable.

Formation, cell testing and diagnostics

Cells produced in the pouch cell line undergo an initial process of formation and quality testing, before extensive electrochemical characterization. IFE also provides a range of testers and other diagnostic tools for further characterization of cells and modules.

- Degradation and ageing studies:

- Charge and discharge curves, current pulse characterization, high precision Coulombic efficiency cycling, entropy spectroscopy, dQ/dV (incremental capacity analysis), electrochemical impedance analysis

- Temperature control: 20 temperature cabinets, ranging from –40 to 70 °C

- Cell testers: PEC and Arbin, 0-50A, 0-5V

- Module tester: Arbin RBT32 (coming fall 2024), 0-250A, 9-150V

- Thermal imaging: Monitoring of battery surface temperatures using IR cameras (FLIR AX65)

- Pressure & temperature sensor foils: Monitoring of pressure/temperature evolution across cell surfaces