Contributions to research & innovation

The new infrastructure is complementary to previous infrastructure in Norway and represents a massive step forward in terms of capacity and capability to the research centres involved and to the wider Norwegian battery ecosystem, as much of it is currently unavailable nationally.

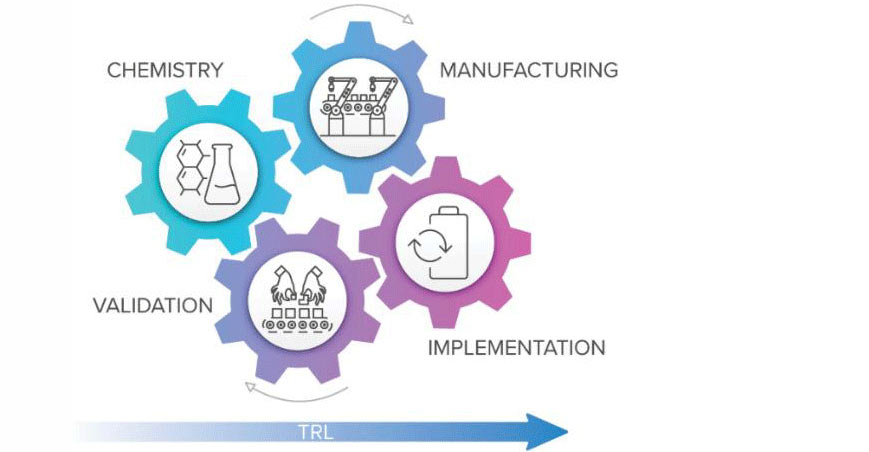

The new research infrastructure is arranged in 4 technology areas and will contribute and provide services within each area according to the needs of relevant research and industrial communities and/or research topics.

Chemistry

NABLA will facilitate the fundamental research activities at Norwegian universities allowing the researchers to focus on preparation of new battery materials, assess their electrochemical performance and understand their electrochemical stability.

Furthermore, improvement and optimisation of current and emerging battery chemistries is founded on understanding and engineering of interphases at the active materials’ surface. High throughput electrochemical testing and world-class operando/in-situ capabilities projected by NABLA will support these efforts by providing a set of tools necessary for understanding of materials’ behaviour and interfaces.

Additional chemical development will be conducted through ALD coating of active materials in powder form and matching of active materials with electrolyte chemistries using high throughput electrolyte screening. Chemistries alternative to LIBs are envisaged to become of high interest and, thus, dedicated equipment necessary to boost research targeting post-LIB concepts will be installed.

The infrastructure for chemistry research is focused on several subtopics: new materials, in-operando studies and advanced post-mortem studies of research-level cells:

New materials: considering the synthesis capabilities at the host research organizations, within NABLA the main focus will be given to the coatings of the materials and equipment for new battery chemistries.

While the new materials could be initially characterized at the host institutions, it is important to evaluate their behaviour in operando. Such studies are of a very high scientific value in the field of batteries and such techniques are considered as state-of-the-art and beyond as they reveal chemical changes in the materials and at the interfaces during battery cycling.

Validation

To be industrially attractive, emerging technologies demonstrated at the laboratory scale require validation at the scale which can mimic production. This includes all aspects of upscaling from synthesis of materials to processability and fabrication of battery cells in R&D pilot cell lines.

Norway has traditionally been strong in production of raw materials, however, evaluation of larger amounts of these materials in batteries has always been conducted elsewhere. The presence of facilities allowing such validation in Norway substantially improves Norway’s position in research and development of battery materials.

Furthermore, it supports the growth of battery-related industry at the early stages by directly providing equipment and expertise that would otherwise be unavailable. In response to the demand in the field, the R&D cell pilot line is designed for flexibility in terms of battery chemistry, with special attention given to reproducibility and traceability.

High-throughput testing of the fabricated cells

The line will also be industry 4.0 ready to meet future research demands (such as adoption of artificial intelligence and digital twins), and high-throughput testing of the fabricated cells.

Manufacturing

Complementary to the cell validation line, a dedicated equipment park is established for the optimization of the various steps in the cell production process and investigating alternative procedures for these. This allows for further investigation of production process improvements and exploration of new technology concepts.

Special attention is given to the optimization of the mixing process: in the conventional LIB production the active materials are mixed in slurry batches before coating of the electrodes. However, there are various concepts for continuous mixing and feeding of slurry to the electrode roll2roll coater; mixing by extrusion being one of them – which is included in this infrastructure.

In addition to the continuous feed, extrusion mixing offers the benefit of short mixing time (a few minutes compared to minimum 0.5-1 hour for batch mixing), reduced amounts of solvents, dry-coating and potential for solid-state battery technology.

Furthermore, a coating unit which couples with new mixing technologies is also included in NABLA. The Manufacturing Technology Area is an ideal tool for both fundamental and applied research, development and innovation for advanced battery cell manufacturing, applicable to academia, research institutes as well as industry.

Implementation

Batteries are relevant for implementation not only in EVs, but in a wide range of applications from high power construction equipment, ferries, express boats and cruise ships to stationary storage in small scale for private homes as well as larger units used for grid support, balancing renewable energy production, peak shaving and frequency regulation. A common denominator for all these areas is the ability to test safety, lifetime, degradation behaviour and other properties at high power (>1 MW) and high voltage (>1000 V).

The NABLA infrastructure offers appropriate test chambers and equipment designed for this purpose, including the possibility to test under controlled temperature and environmental conditions.

Second life

As a result of the rapid growth of electrification in Norway, especially in the EV market, we will be exposed to large volume reuse and recycling challenges/opportunities before most countries. This advantage represents an opportunity for new value creation from used LIBs within refurbishing, secondary use, recycling, and new energy systems and models.

Second life batteries are particularly relevant for stationary applications, such as those mentioned above. The proposed research infrastructure will enable the characterisation of decommissioned EV batteries and application-based sorting and grouping of battery packs, modules, and cells.

In addition, a post-mortem line where used cells can be opened and characterised or further transferred to more advanced characterisation equipment will be available for more thorough investigation of degradation behaviour.

Safety and ethics

A NABLA requirement has been the establishment of a flexible and safe e-infrastructure. In-homogenous data is expected, as well as large span of user types (different skills, needs, security and IPR requirements). A dedicated WP is therefore established to address this challenge.

Even though ethical issues are not expected, routines to report and address them quickly will be put in place and appropriate measures will be enforced by the Steering Committee.

The potential for undesirable effects on animal health and environmental due to the use of NMP as solvent when making cathode electrodes is handled by NPM scrubbers located at both cell lines.

All operations that will be conducted in the project will be subject to an approval of a safe job analysis by the responsible at the host institute/institution before implemented. All safe job analyses will be made available to the leader group and the Steering Committee.